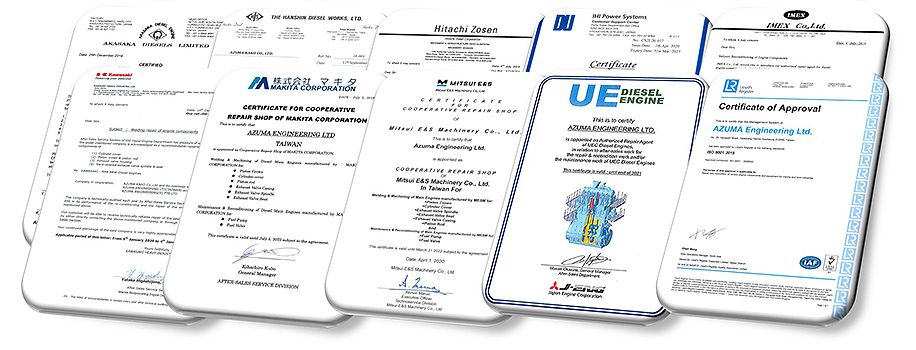

CORPORATE HISTORY

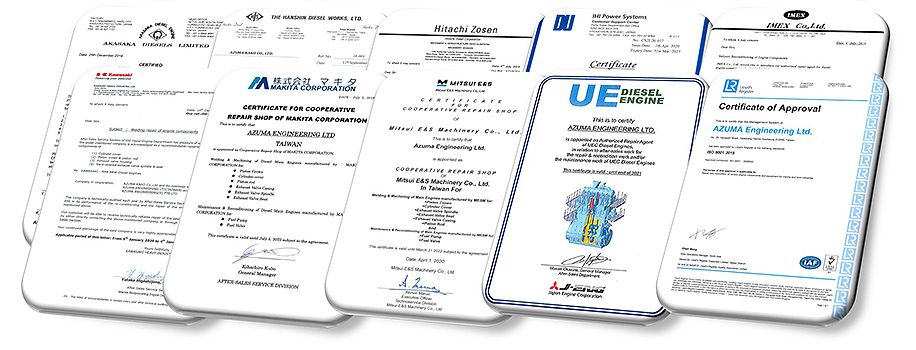

AZUMA Engineering Ltd. is an excellent company with over 30 years

of service history that was established in December 1987.

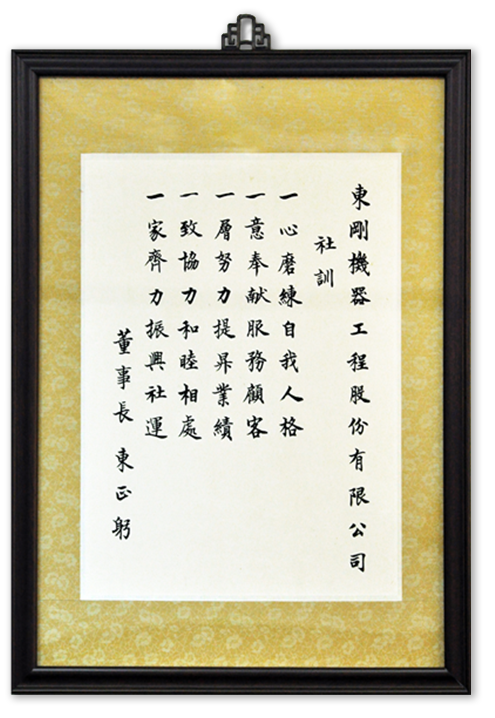

Under the management of current chairman Mr. TOSHIMITSU AZUMA,

AZUMA Engineering Ltd. persist in the faith of "honesty" and "integrity"

to serve the vast number of customers.

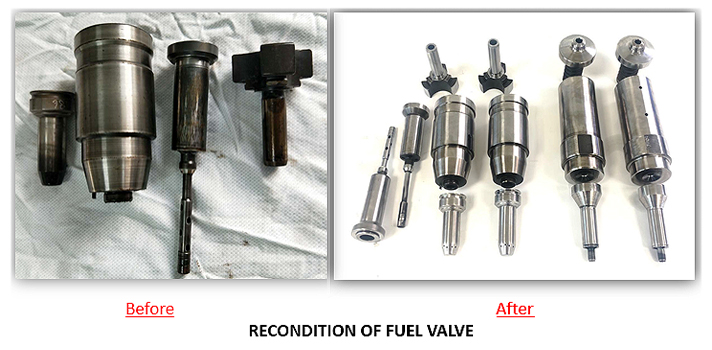

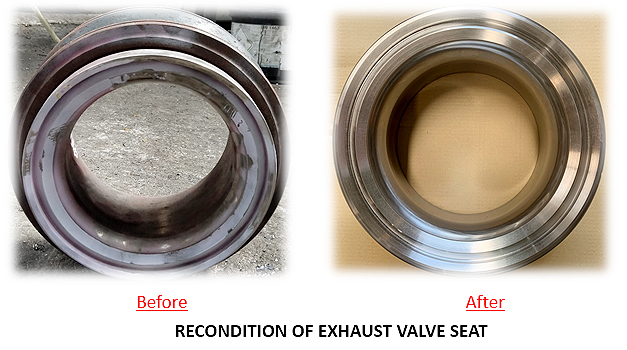

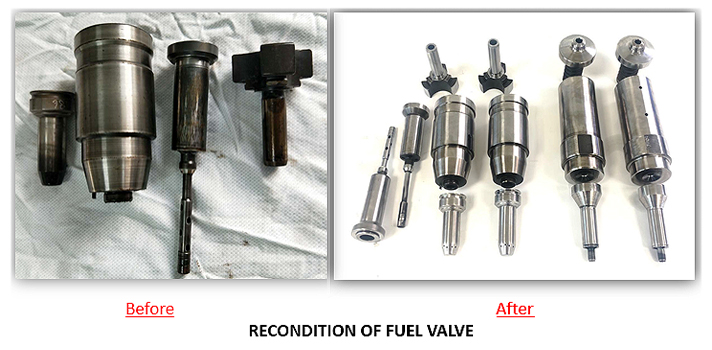

Our company main services were ship engine

【M/E & A/E Components Recondition】、【Ship Repair】、【Spare parts Supply】、

【Propeller Repair】、【Nozzle Repair】、【Other Repair】, etc.

Until now, we have served domestic and foreign customers such as

”EVERGREEN”.“WAN HAI”. “YANG MING”. “YU MING”. “TNC”. “K-LINE”. “CHINA STEEL”.

“CPC”. “MING TAI”. “DANAOS”、“V-SHIP”、“APL”、“F LAEISZ” etc.

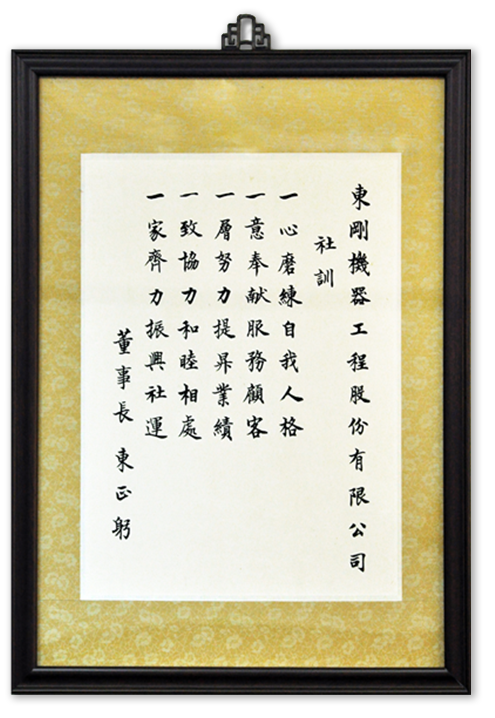

All out discipline to enhance self-personality.

Wholeheartedly dedicate to serve customers.

Spare no effort to advance outstanding accomplishment.

Hardworking jointly and get along in racial harmony.

Unit together and devote to prosper company’s fame.

AZUMA ENGINEERING LTD.

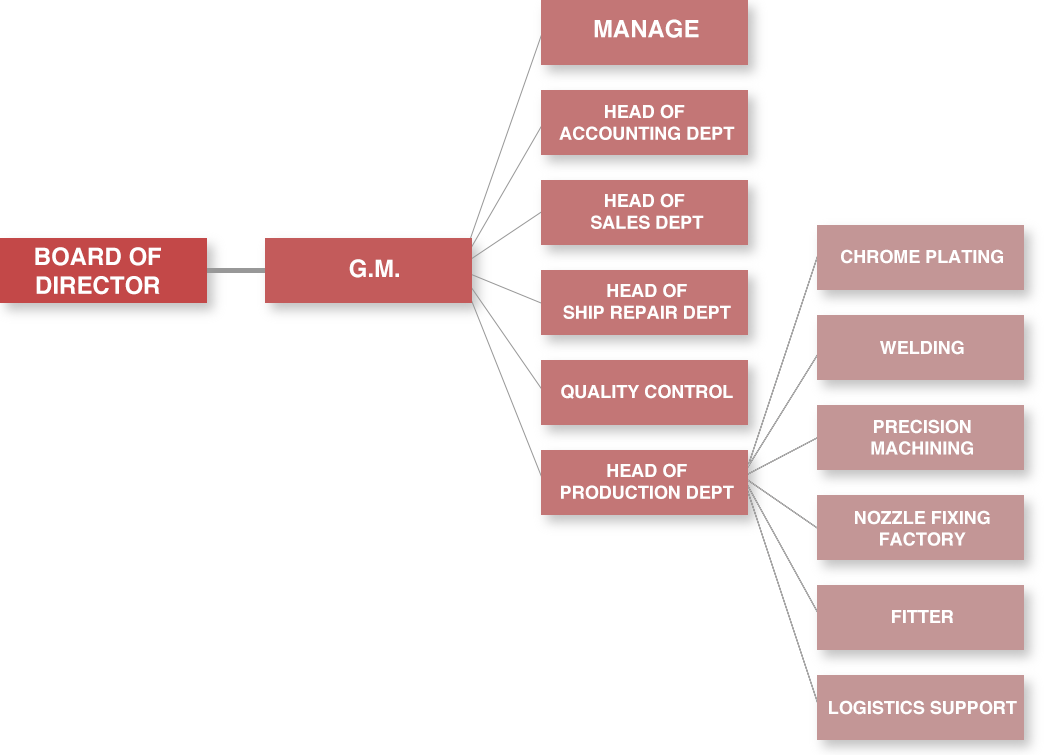

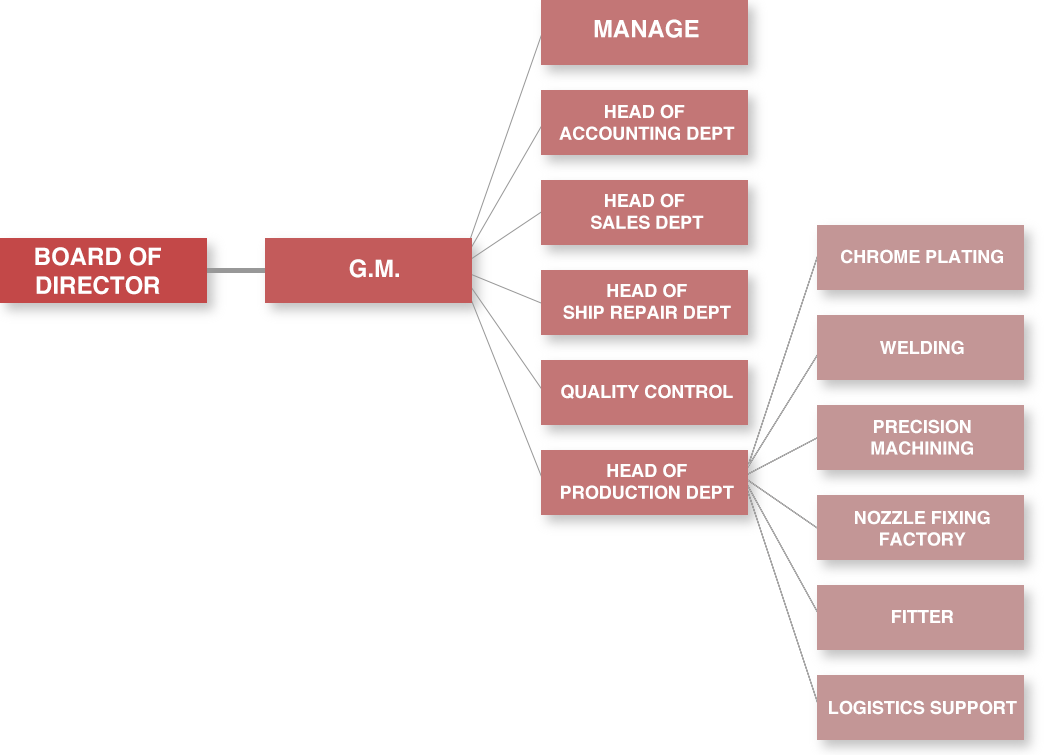

ORGANIZATION CHART

AZUMA ENGINEERING LTD.

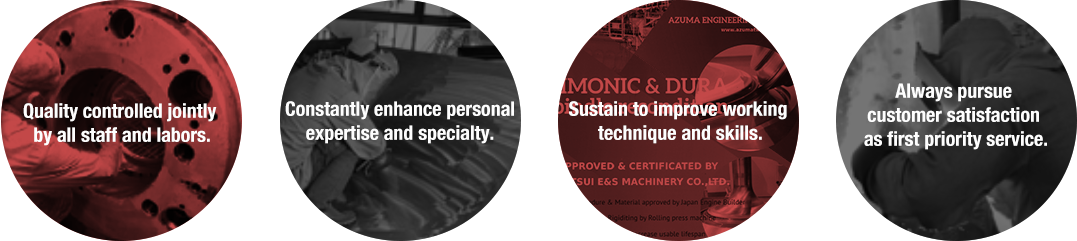

QUALITY POLICY

AZUMA ENGINEERING LTD.

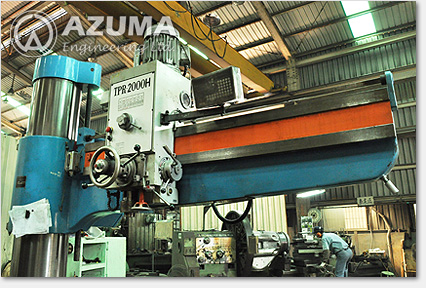

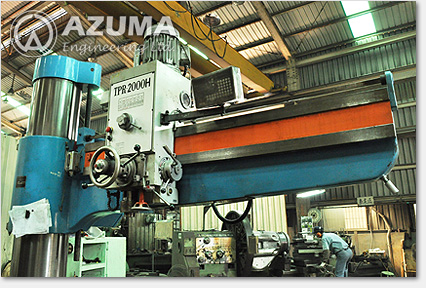

IMPORTANT EQUIPMENTS

Overhead Crane (10Ton*1/5Ton x 2 /2.8 Ton*1) x4

Submerged Arc Welding Machine (OTC Japan*2) x2

MIG Welding Machine (ESAB Sweden*1/OTC*1) x2

TIG Welding Machine (OTC Japan) x2

SMAW Welding Machine (Taiwan*1/Japan*7) x8

Vertical Lath Machine (Dia.2000mm) x1

Horizontal Lath Machine (Taiwan) x6

Grinding Machine (Taiwan*1/Japan*1) x2

Universal Drill Machine (Germany) x1

Radial Drill Machine (Taiwan) x2

Plasma Cutting Machine (USA) x1

Chrome Plating Facility (Including accessory) x6 TANKS & 7 SETS

Annealing Furnace (Including accessory) x1(620±25℃)

Annealing Furnace (Including accessory) x1 (Max 1000℃)

Rolling Press Machine for Nimonic & Dura Spindle (Mitsui E&S)x1

Truck (17Ton, 11Ton, 7.5Ton) x 3�Compressed Air System x 4�Forklift (3 Ton) x 1

AZUMA ENGINEERING LTD.

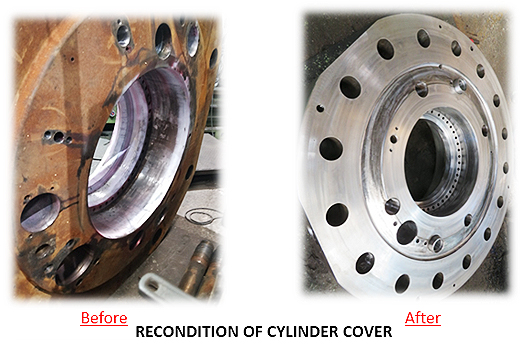

PRODUCT RECORD

Until now, the maximum capacities which were fully or partially reconditioned are recorded as below :

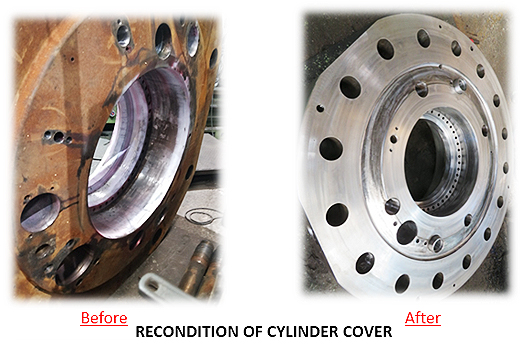

| Cylinder Cover |

RTA96C & 98MC |

| Piston Crown |

RTA96C & 98MC |

| Spindle |

98MC-C |

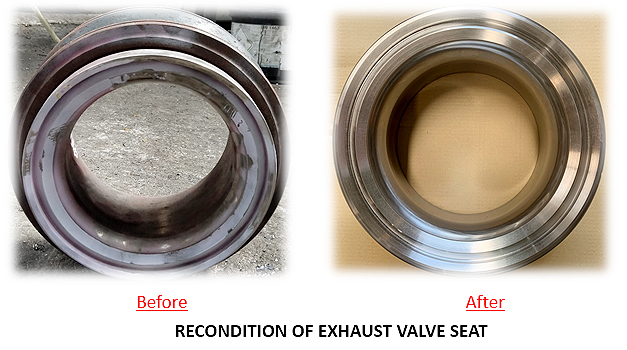

| Seat |

K98MC-C |

| Piston Rod |

RTA96C & K90MC-C |

| Chrome Plating |

25 Pcs/Month |

| M/E & A/E Nozzle Maintenance |

500 Pcs/Month |

AZUMA ENGINEERING LTD.

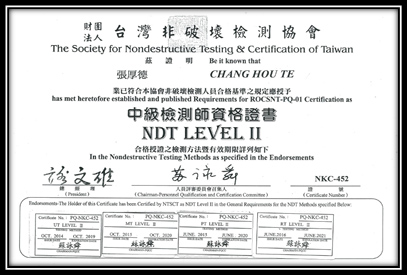

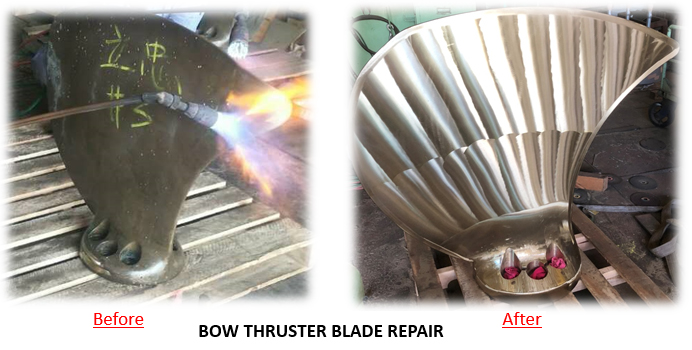

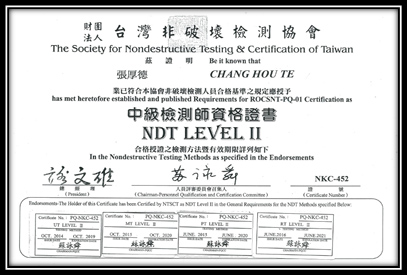

EXCLUSIVE EXPERTISE

Until now, AZUMA TAIWAN have exclusive expertise of marine recondition process as follows:

Latest technology of NIMONIC & DURA SPINDLE recondition.

Repair by Low Temperature Welding technique of all kinds of carbon iron component.

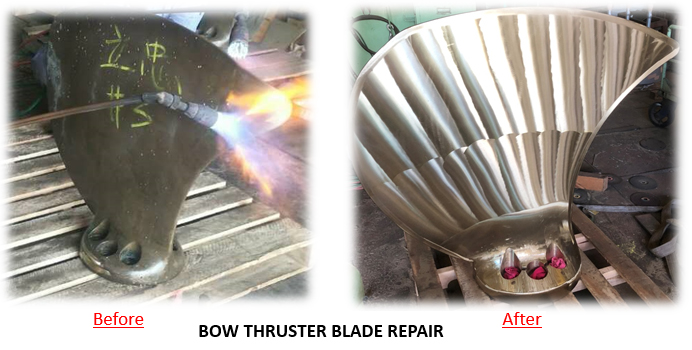

Repair of damaged propulsive blades by preheating, forming, cutting, welding, balancing and super polishing techniques.

Turbo charge disassembly, Installation and dynamic balancing test.

All kinds of marine piping replacement, welding and get change new one.

All kinds of marine engine emergency repair and replace accessories.

All kinds of marine M/E & A/E nozzle maintenance/replace the accessories.