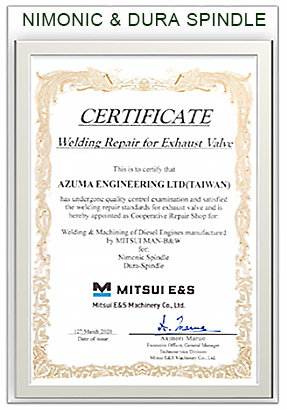

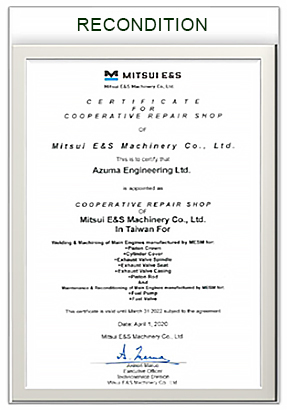

RECONDITION

All of well known marine main engine, auxiliary engine and its accessories such as MAN B&W, SULZER,UEC,YANMAR,PIELSTICK etc.. We are capable to recondition its components by means of welding, precision machining, chrome plating, heat treatment, NDT inspection etc. expertise and experience.