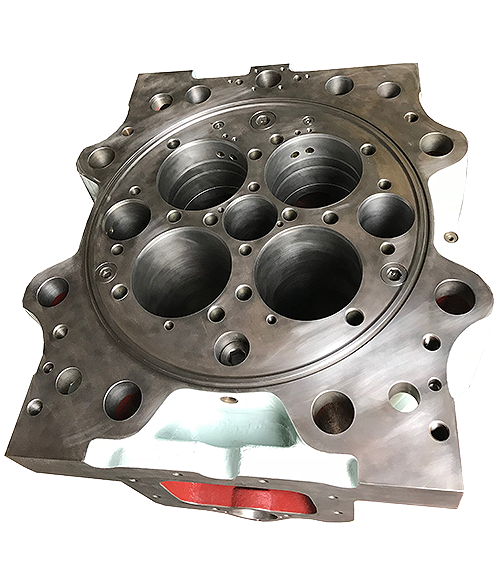

All of well known marine main engine, auxiliary engine and its accessories such as

MAN B&W, SULZER,UEC,YANMAR,PIELSTICK etc..

We are capable to recondition its components by means of welding, precision machining,

chrome plating, heat treatment, NDT inspection etc. expertise and experience.

The working procedure and consumables we implement are exactly in conformance

with the Maker Specification and Drawing.

Even the Quality Control Inspection follows strictly to Maker Standard as well.

Therefore we have been awarded certification and authorization from engine makers. In addition,

the relevant Class grants us its certification to our quality as well.

These are positive evidence that our service and quality are exclusively confirmed worldwide.

| Component Name | M/E | A/E | Full Recon | Partial Recon | As per owner's | Remark | |

| 1 | Cylinder Cover | × | × | × | × | ||

| 2 | Piston Crown | × | × | × | × | Ring Groove Chrome plating. Combustion Surface Inconel layer. | |

| 3 | Exhaust Valve Spindle | × | × | × | × | ||

| 4 | Exhaust Valve Seat | × | × | × | × | ||

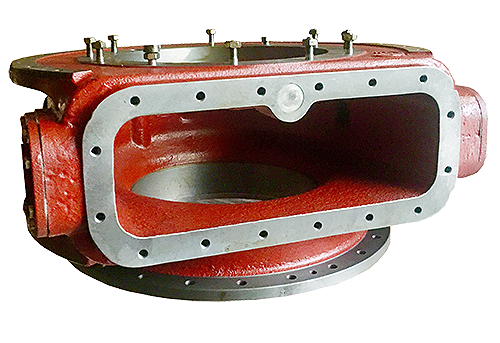

| 5 | Exhaust Valve Housing | × | × | × | × | ||

| 6 | Piston Rod | × | × | × | |||

| 7 | Piston Skirt | × | × | × | Renew Copper Band | ||

| 8 | Valve Cage | × | × | × | |||

| 9 | Ex. Valve Air Cylinder | × | × | ||||

| 10 | Cylinder Head | × | × | × | |||

| 11 | Piston Crown | × | × | ||||

| 12 | Crank Shaft | × | × | ||||

| 13 | Connection Rod | × | × | ||||

| 14 | Exhaust Valve Spindle | × | × | × | Fabricate New | ||

| 15 | Fuel Valve | × | × | × | × | ||

| 16 | Fuel Pump | × | × | × | × | ||

| 17 | Plunger and Barrel | × | × | × | × |

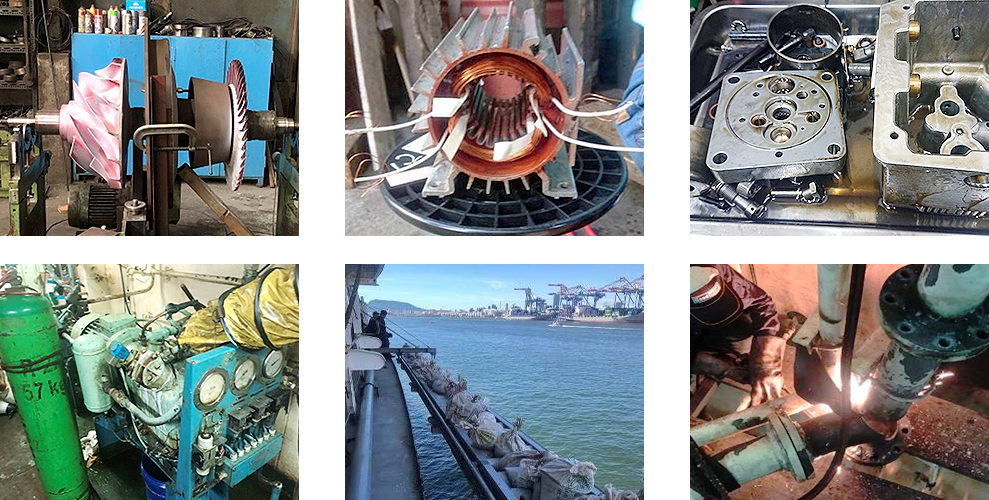

In conjunction with subcontractor’s capability,

we are qualified to maintain and repair various onboard systems and equipment such as Main

Engine, Auxiliary Engine, Hull, Outfitting, Electrical, Communication and Propulsion etc..

So far, the following specified items were completed successfully by us. They are Main Engine,

Diesel Generator, Electrical Motor, Air Conditioner, Chilly Water Unit, Elevator, Governor, Turbo Charger,

Windlass, Anchor, Boiler, Life Saving Apparatus, Miscellaneous Gauge, Hull, Cargo Hold, Hatch Coaming,

Gangway, Lifting Crane, Engine Bedplate, High Pressure Pipe and Heat Exchanger etc..

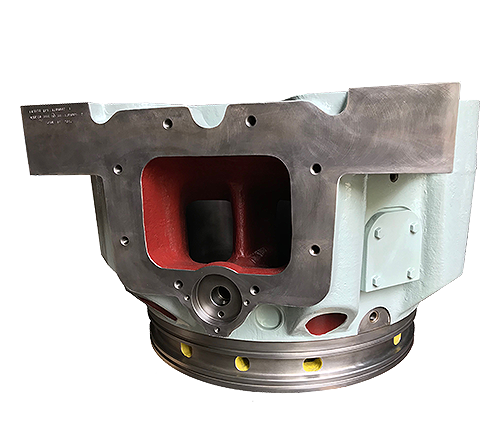

We can supply all necessary spare parts for auxiliary engines,

electrical equipment and its systems in accordance with ship owner’s requirement.

So far, we have successfully supplied A/E Cylinder Liner, Piston Skirt,

Casing of Turbo Charger etc. to customers.

There is also certificate issued by Class and attached

with brand new spare parts to ensure quality and guarantee.

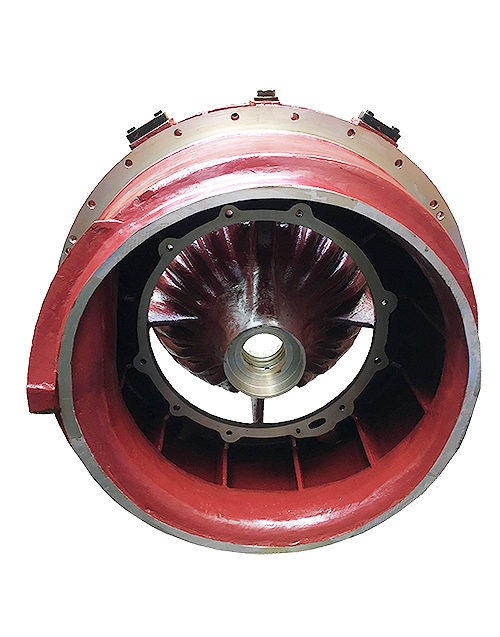

Accidental damages such as HIT BENT, CHIP, CRACK, MISSING and PITTINGS caused from CAVITATION

to the propulsive propeller blade, bow thruster blade and propeller cap etc.

can be repaired in conformity with Maker Specification.

To make use of PREHEATING, FORMING, CUTTING, WELDING, GRINDING, BALANCING and SUPER POLISHING expertise,

all of the apparent defects will be recovered to its original specification and performance.

The working procedure, implements, applicable consumables and quality control standard etc.

will be submitted for approval prior to commencement and inspected acceptable

by ship owner along with surveyor from relevant Class afterwards.

So far, record of maximum propeller repair job completed by AZUMA Engineering Ltd. is as below.

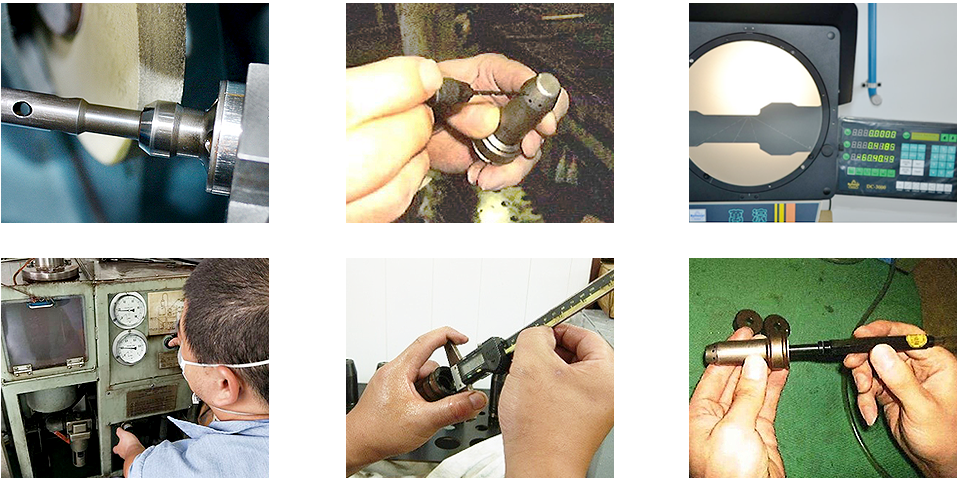

In order to satisfy the customer, send colleagues to MITSUI in Japanese and SINGAPORE Branch

for trained the M/E & A/E nozzle of dismantling and repair, and got certificate.

After maintenance energy was established, the nozzle maintenance factory was established in July 2012. So far,

it has maintained more than 500 PCS/M.

Each nozzle maintenance process are in line with the original factory

standard size and pressure test confirmation can pass the inspection.

We have accumulated vast experience of reconditioning and ship repair over past three (3) decades.

In addition, we collaborate closely with domestic subcontractors specialized in different categories

and keep good relationship between each other.

Owing to our work service and quality are confirmed by ship owners and shipping companies,

therefore we can also offer miscellaneous services such as site survey and assessment for vessel,

dispatch experienced personnel, technical assistance, personnel training, damage survey,

evaluation analysis and report, technical documentation etc.

to fulfill various enquiry from customer.